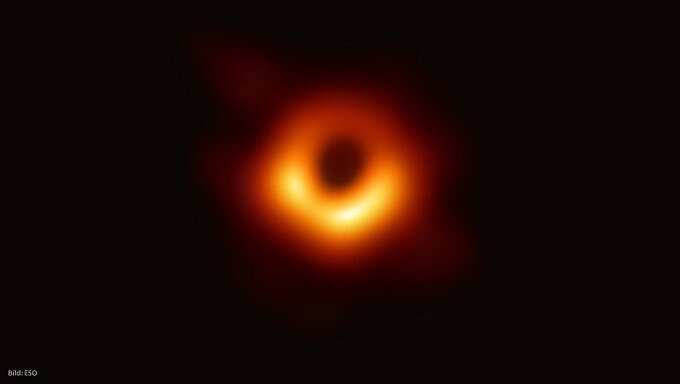

An asphere or aspheric lens is an optic whose surfaces are defined by a polynomial equation. Aspheres are rotationally symmetrical around the optical axis, but their radius of curvature changes with the distance from the center. Aspheric lenses provide higher performance compared to conventional lenses, allowing a reduction in size, mass, and number of elements used – important features for miniaturization. Manufacturers of medical instruments, telescopes, and cameras use aspheres to improve their products. As the saying goes, “Where there is light, there must be shadow” and in the case of aspheres, the production and metrology of such lenses requires more complex and innovative technologies compared to traditional lenses.

There are several methods to quantify the surface accuracy of aspheres, both contact and non-contact devices are used by different manufacturers.

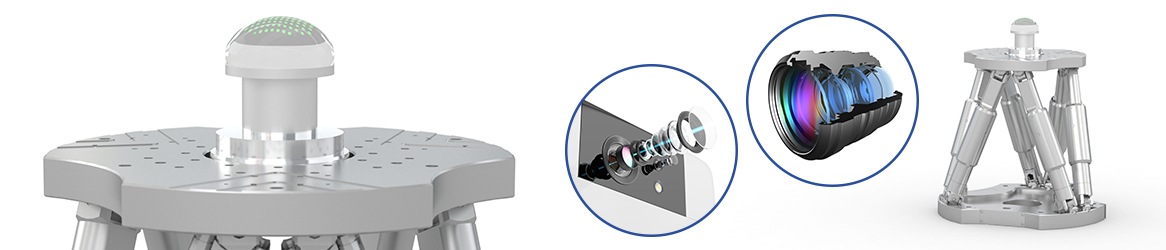

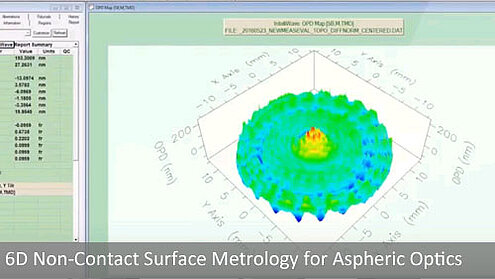

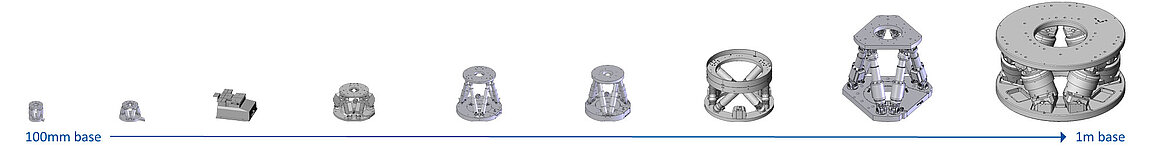

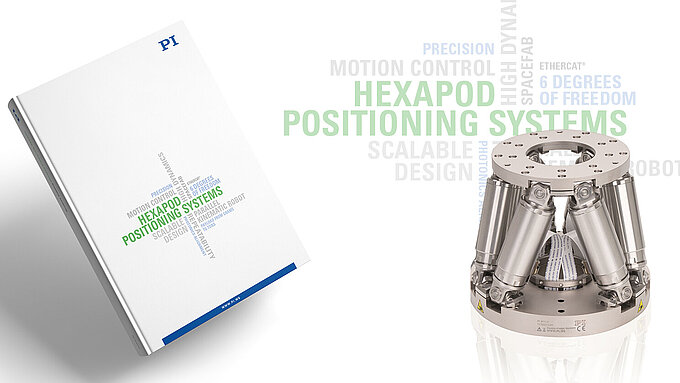

A novel non-contact metrology method called “Tilted Wave Front Interferometry (TWI)” makes use of the multi-axis flexibility and accuracy of hexapod parallel kinematics 6-axis motion systems to position a calibration sphere.

The new method, implemented by metrology specialist Mahr, now combines speed and flexibility into one process. The new machine can measure surface shapes with high lateral resolution directly on the production line. The measuring uncertainty is less than 50 nanometers.

The Measuring and Referencing Process

The new metrology system acquires several subapertures that are active at different times and combines the individual interference patterns to form a single pattern. A highly precise positioning system with <0.5µm repeatability and <5µm lateral position accuracy is required, to allow meaningful data acquisition with a calibration sphere.