During surgery, it is critical that the surgeon has real time evaluation of blood vessels in order to make assessments related to the flow of blood. Piezo transducers are at the core of modern blood flow monitors.

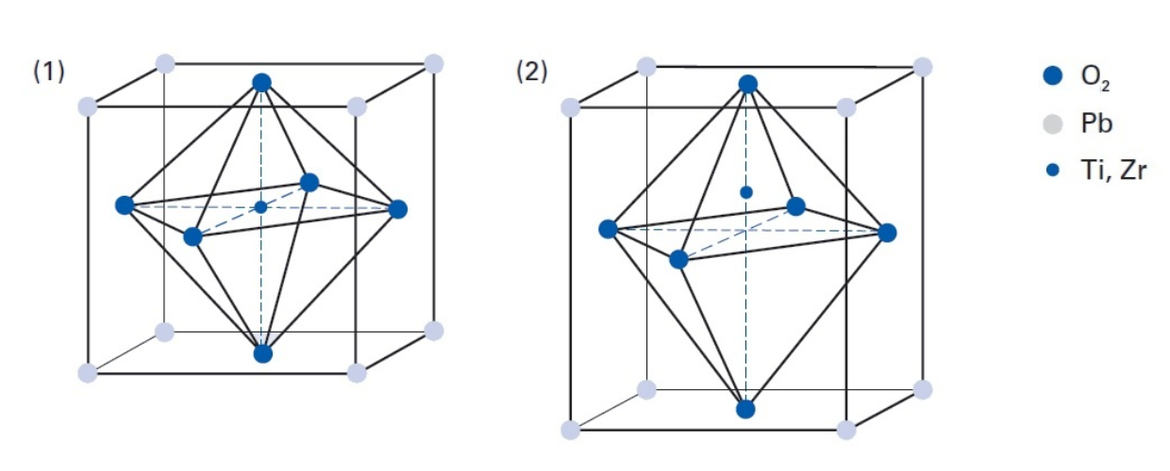

The piezo effect (generation of electric charge under pressure, or mechanical deformation when an electric field is applied) is found in some natural materials, such as quartz, but much better performance is achieved with special Piezo ceramic materials such as PZT (Plumbum Zirconate Titanate).

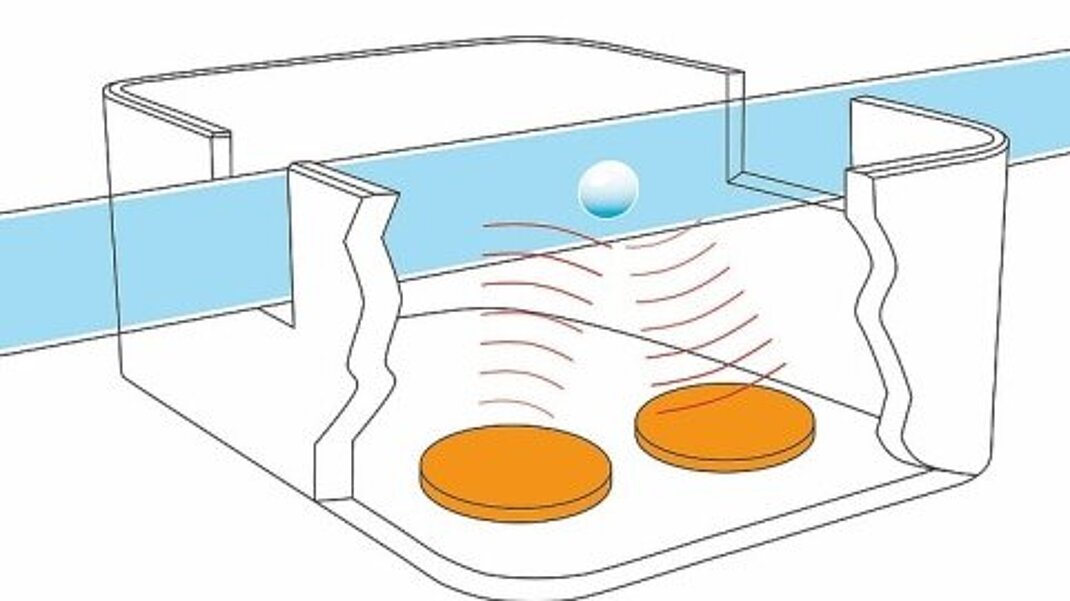

Modern piezo transducers can emit and detect high frequency sound (often in the range of 5 to 10 MHZ), when used with special electronic amplifiers. Ultrasound pulses from the probe placed near the vessel, bounce off the blood and, with the help of the Doppler Effect, can give an accurate measure for the flow velocity of the blood or just an audio signal equivalent to the flow.

PI Ceramic provides different Piezo formulations for specific applications.

PIC255 material is recommended for use in Doppler applications for these reasons:

- High permittivity

- High coupling factors

- High charge constant

- Low mechanical quality factor

More information on piezoelectric materials

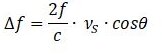

The Doppler Effect

The Doppler Effect can be used to measure the flow rates or flow velocities of liquids, suspended particles or air bubbles. After the transducer emits an ultrasonic pulse, the ultrasonic waves (f0) are scattered or reflected by liquid particles. The resulting frequency shift of Δf between the transmitted and reflected wavefront (one transducer can be operated as transmitter/receiver) is proportional to the flow velocity vS of the particles. The angle θ between the direction of the emitted ultrasonic pulse and the measuring path must be taken into account:

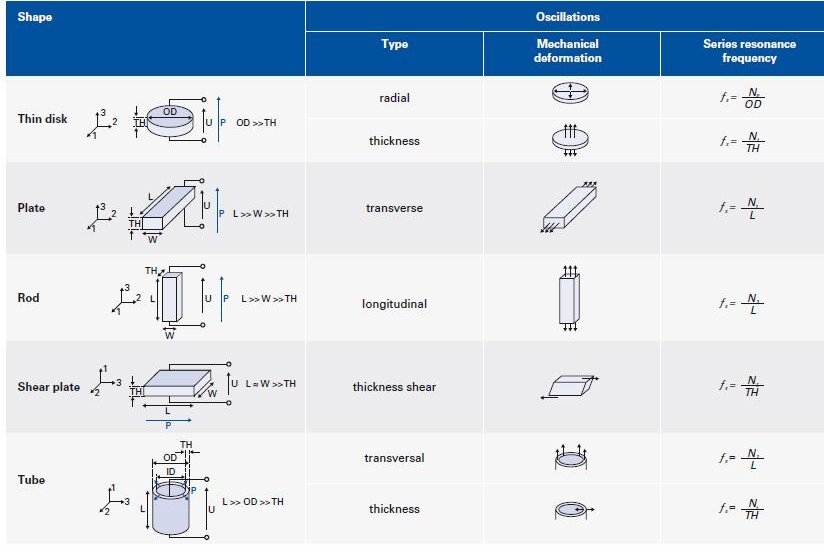

Since devices for critical medical application are FDA approved, long-term reliability and consistent performance of all components are essential for production. PI Ceramic can provide consistent batch to batch performance in small form factors such as plates or discs with specialty electrode configurations for easy probe integration, and value-added assemblies.

Consistency is based on our complete control of the piezoceramic manufacturing process from raw materials to final quality assurance, including strategic stocking of all critical materials. With 350 employees dedicated solely to manufacturing the highest quality PZT components on the market, we set the tone for your acoustic flow monitoring application.