PI provides a variety of innovative active optical alignment products from piezo-based scanners, motorized fiber positioners to high-throughput, automated sub-systems for applications in silicon-photonics (SiP), optics manufacturing, data communications, and for packaging-automation. High-performance controllers use firmware-based routines for simultaneous optimization of several inputs and outputs. Integrated routines make it possible to perform single-axis alignments up to complex, multi-axis fiber array positioning within the shortest possible time. All systems come with extensive software for easy setup and integration.

Fast Multi-Channel Photonics Alignment Systems

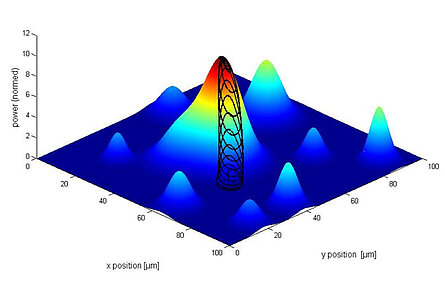

PI’s Fast Multi-Channel Photonics Alignment (FMPA) systems are based on a highly specialized digital motion controller (E-712) and a hybrid active alignment mechanism to achieve the required long travel ranges without sacrificing stability, resolution or alignment speed. FMPA is implemented in the E-712 controller’s modular firmware to enable fast, simultaneous alignment and tracking of multichannel couplings in multiple degrees of freedom. The efficient algorithms for first light detection, area scanning, and gradient search guarantee highest throughput in 24/7 operation.

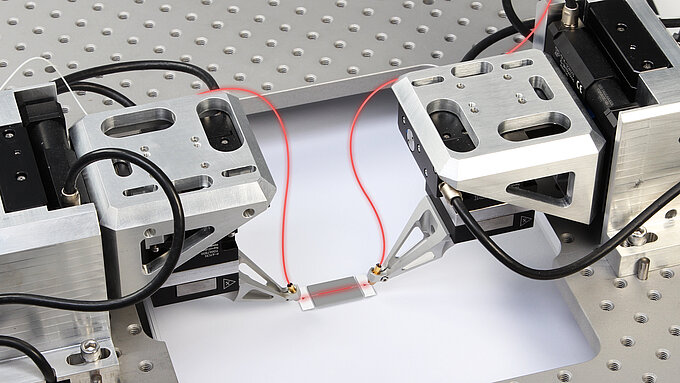

Hexapods for Alignment

PI‘s hexapod-based photonics alignment systems provide 6 degrees of freedom motion. The hexapod controller has many built-in routines for commands finding first light and optimizing the alignment. An optional analog input can be used with optical power meters. The user-programmable pivot point is a significant advantage – it can be set to any location, for example the tip of a fiber, the waist of a beam or the surface of a SiP wafer.

Modular Alignment Engines

Modular alignment engines are based on a combination of linear stages and goniometers for rotation. In the case of the F-131, a Piezo XYZ scanner is mounted on an XYZ motorized stage for long travel. The piezo scanner allows for ultra-fast scanning and alignment, or for mapping the output characteristics of an optical device in fractions of a second.

Downloads

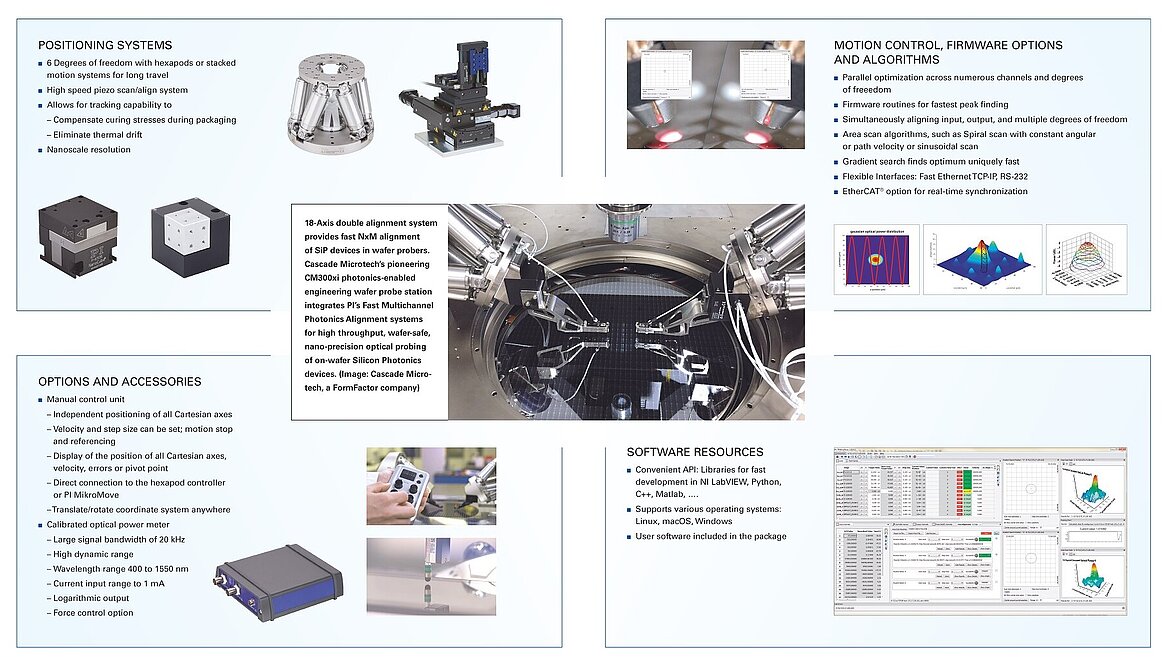

Overview: System Components for Automated, Fast Multi-DOF Alignment

Gain Reliability and Save Development and Process Time

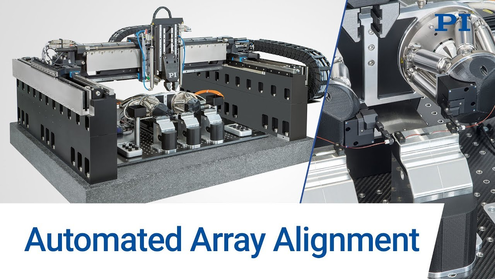

Practical Examples of Parallel Alignment Automation

Alignment for Optics and Silicon Photonics

Fast Multi-Channel Photonic System