High-Precision Motion and Control Solutions for Your Applications

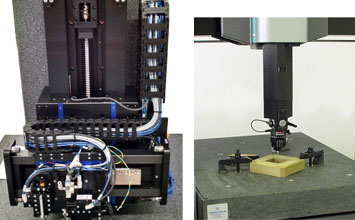

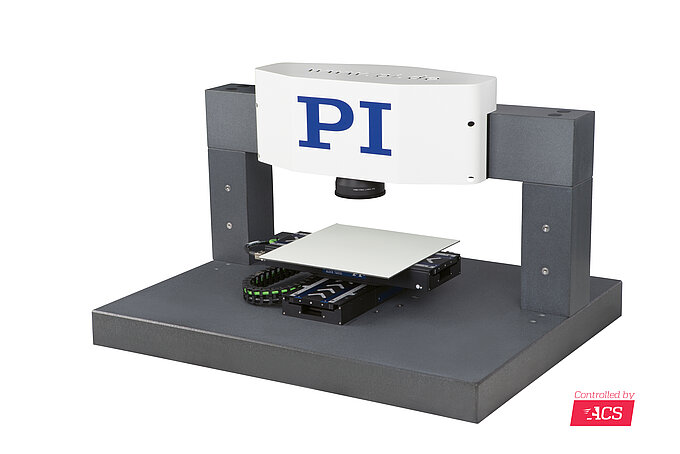

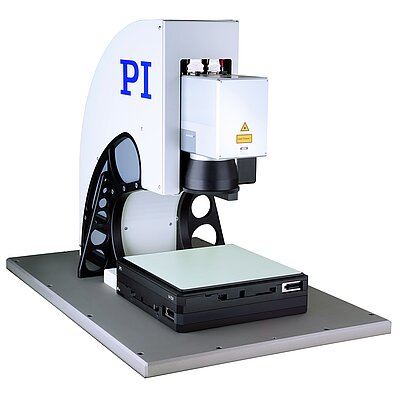

Turning ideas into advanced motion solutions that enable our customers to improve their applications and shape future markets is what drives us at ACS and PI. Thanks to our in-depth expertise in piezo technology, nano positioning, and performance automation – combined with a wide range of technologies and a high level of vertical integration – we can meet the specific requirements of a variety of applications. Our solutions range from single components to complex multi-axis solutions, including controllers, drives, and application specific firmware, as well as software.

Discover what ACS and PI can do for you.

Join us at Machine Building Live on the 4th of October to gain a deeper understanding of how our technologies can drive your projects forward from nanometre-level precision to high dynamic performance.

REGISTER FOR FREE ADMISSION HERE

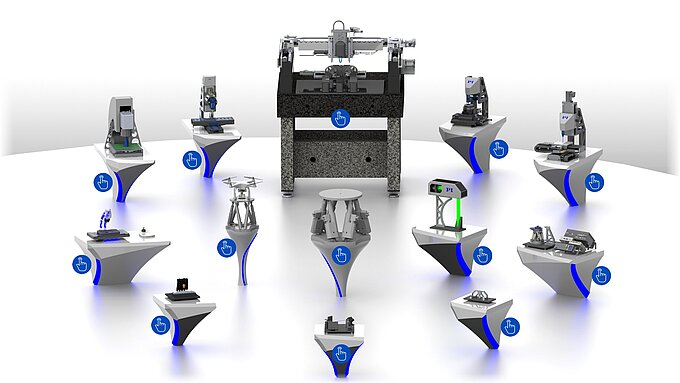

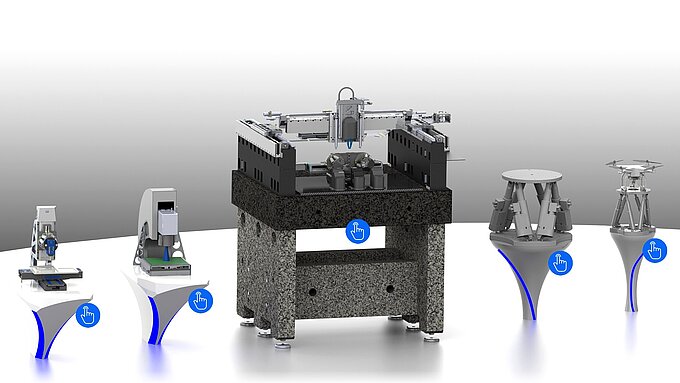

Examples of High-Precision Performance Motion Control, Positioning and Drive Solutions from ACS and PI:

Clear Concise Guidance from the Experts

Do you have questions about our solutions? Our specialists are happy to help you!

Fill out the form below and our Applications Engineers will get in touch.

Are you looking for help with your high-precision motion control application?

You have come to the right place!

PI has the UK's expert application engineers who are ready to help you solve your technical problems.

In order to develop the appropriate positioning and motion control solution that can also be optimally integrated into the application, PI works closely with its customers right from the start. Due to the variety of technologies and experience in precision positioning and automation, PI can react flexibly to the requirements of your technology and offer motion solutions that meet customer needs:

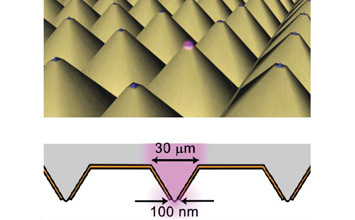

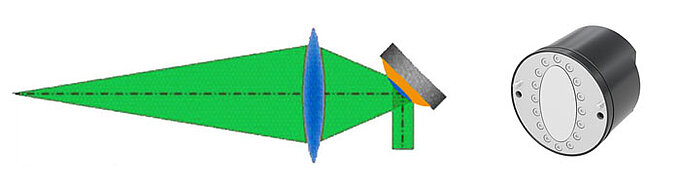

- From single and multi-axis systems to highly customised solutions where the motion of galvanometer scanners and the positioning systems have to be synchronised and are able to run simultaneously.

ACS Motion Control, as part of the PI Group, allows the supply of highly sophisticated automation and motion controllers with a wide range of drive options and dedicated modules for the control of laser applications.

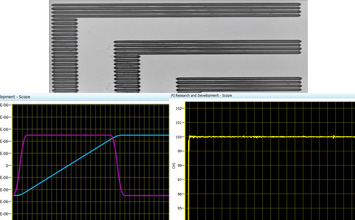

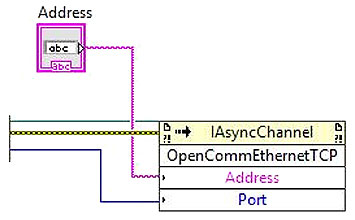

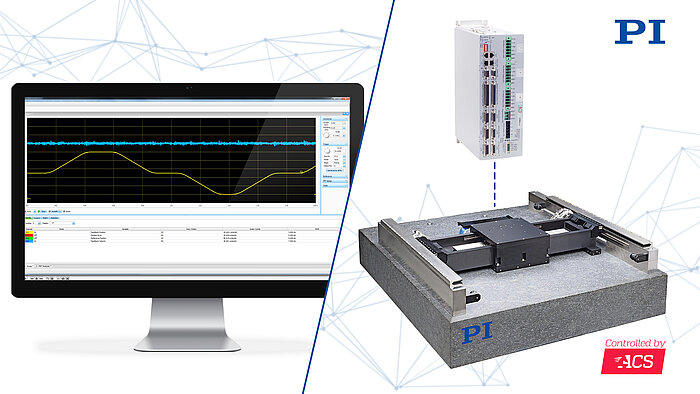

Accelerate Development with Motion Application Simulation

The SPiiPlus Simulator is designed to meet the needs of high-tech OEM machine builders. Included in the SPiiPlus ADK Suite software package, it enables streamlined development of applications at the controller- and host-level without connecting to any hardware. A robust simulation of the machine can be developed using ACSPL+ programs to execute process recipes, emulate responses to inputs and fault conditions, and more.

For more information about high-performance motion and control solutions for improving throughput and precision in laser applications, and anything of this sort, your best first place for information is to ask Neil Beaumont your local PI applications engineer.

Understanding your individual needs to build our futures together

Understanding your individual needs to build our futures together

- Market-proven solutions for laser processing

- Competent advice - right from the start

- Flexible configuration and application-specific adaptation

- Different integration levels and high integration capability

- Comprehensive solutions that combine ease of use and smooth operation while increasing productivity

- High economic profitability

- Servicing and support - Always near you - worldwide

- Better Thoughput | Higher Accuracy | Faster Development | Greater Flexibility

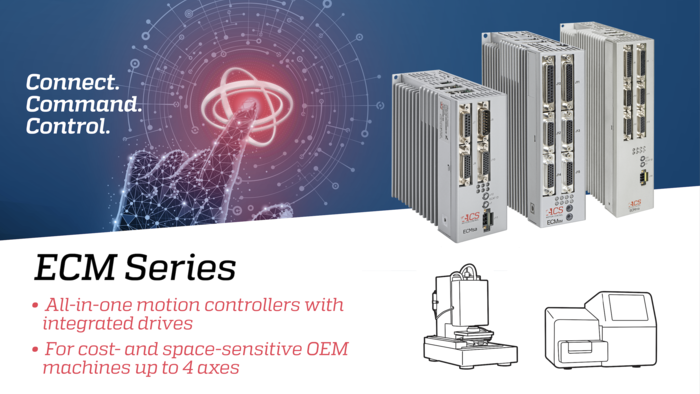

ECMma

2 or 4 Axis Motion Controller with Integrated Servo Drive up to 10/20A at 150VDC

- Compact Industrial Package for Streamlined OEM Integration

- Rich Host Programming and Simulation Tools for Faster Software Development

- Universal Motor Support for Maximum Motor/Stage Flexibility

- Simple Configuration and Tuning with SPiiPlus MMI Application Studio

- Max Drive Current: 10/20A at 150VDC, 15/30A at 100VDC

- Drive Supply Input: 24-150VDC

- Feedback Channels: 4 (AqB, SinCos, or Absolute)

- Analog I/O: 4/2

- Digital I/O: 12/12

- Functional Safety: STO, SS1

IDMma

2 or 4 Axis DS402 EtherCAT® Intelligent Drive Module up to 10/20A at 150VDC

- Communication Protocol: EtherCAT DS402 (CiA402) CoE

- Max EtherCAT Cycle Rate: 4kHz

- Real-Time ACSPL+ Program Threads: 4

- Drive Axes: 2 or 4

- Drive Supply Input: 24-150Vdc

- Bus Voltage: Equal to drive supply input

- Max Current Output Per Axis: 15/30A up to 100Vdc, 10/20A up to 150Vdc

- Mounting Type: Panel

- Functional Safety Options: STO & SS1

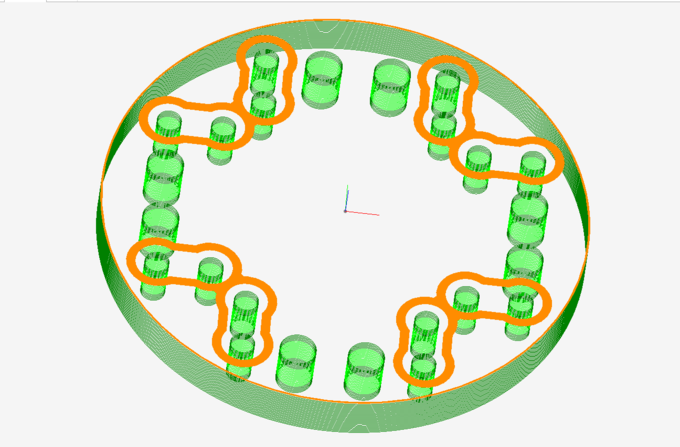

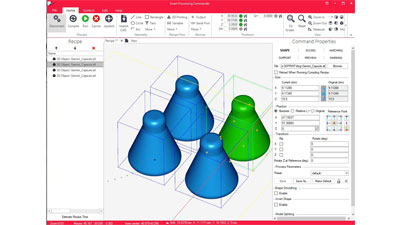

SPiiPlusSPC Smart Processing Commander

Machine Control Interface for High-Precision Laser Processing Applications

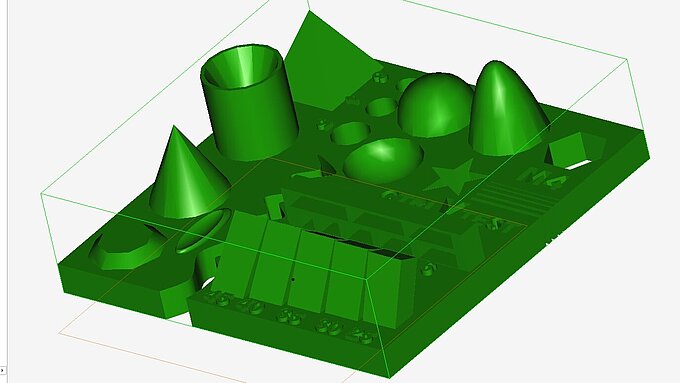

- Flexible CAD-to-motion import and design

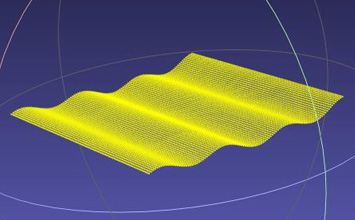

- 2D and 3D processing modes

- Laser Control Module support for accurate fixed beam laser triggering, dynamic power control

- Dynamic Position Monitoring

- Flexible processing architectures

- Rich galvo scanner and vision system calibration features

- Pre-developed support for leading galvo, laser, and camera suppliers

- Customization Options via C# plugins

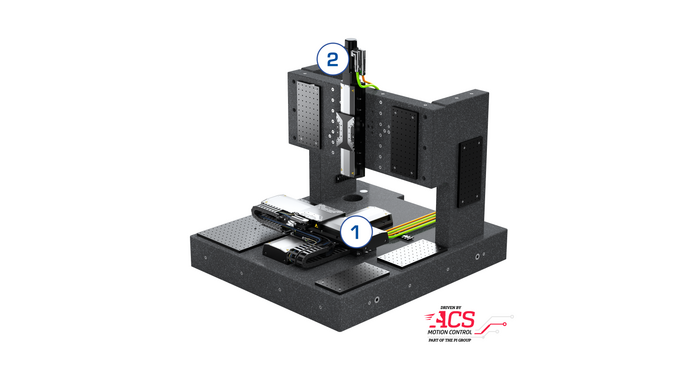

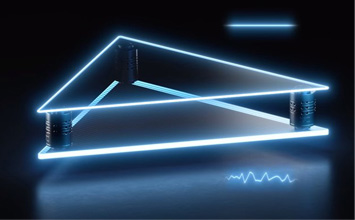

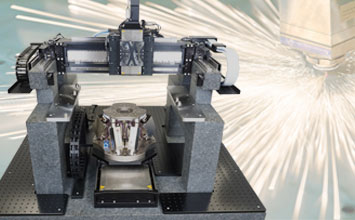

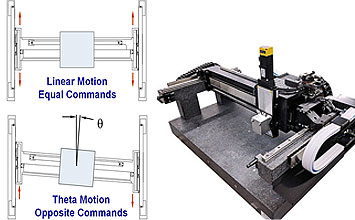

Smarter Gantry Control

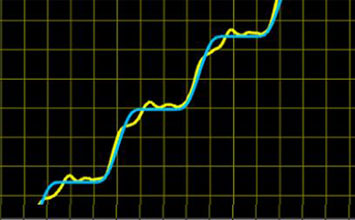

Improve Throughput and Accuracy with Advanced MIMO Control Algorithm

- MIMO decoupled control of linear position and yaw displacement loops

- Independent tuning and optimization of linear and yaw control loops

- Dynamic cross-axis center of mass compensation

- Error mapping compensation (orthogonality, straightness...)

- Dual-loop gantry control

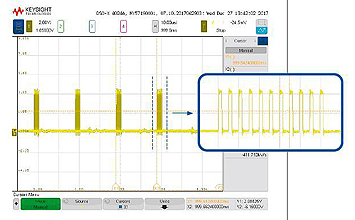

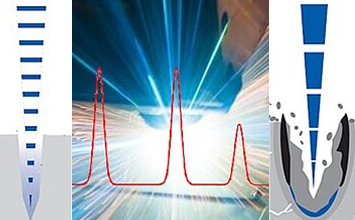

LCM EtherCAT® Laser Control Module

Enables direct control of a laser source with full synchronization to motion

- The LCM is designed to meet the needs of laser processing system OEMs with demanding throughput and accuracy requirements.

- Working under any ACS SPiiPlus Platform EtherCAT master controller, the LCM tightly synchronizes control of a fixed beam laser with motion.

- Sub-microsecond latency enables high-accuracy laser micromachining, while high pulse frequencies enable high levels of throughput.

System Optimisation and Support

UK based support tailored to your needs

- System implementation, mechanics, controller and peripheral devices

- System optimisation including tuning

- Fault diagnosis including root cause analysis and corrective action

- Training

Contact us today.

Clear Concise Guidance from the Experts

You can find out more about our broad portfolio for Performance Automation here.

Downloads

ACS Product Map

ACS Product Map

ACS Sales Brochure

ACS Sales Brochure

Automation Platforms for Laser Material Processing

Precision – Throughput – Synchronized Motion

Advanced Control Technology for Laser Material Processing

How to make it easier for system integrators to design and build advanced systems for a new age of laser applications