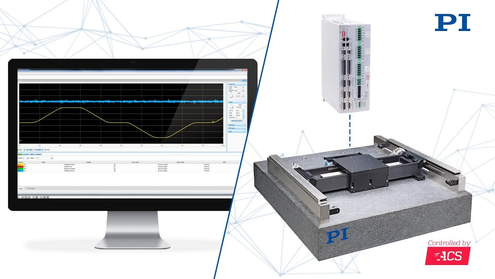

A centralised automation platform providing coordinated motion for complex profiling applications based on a real time EtherCAT network.

Helping you:

- Improve productivity

- Increase the precision of your process

- Enhance the quality of what you produce.

- Tools to synchronise motion with lasers, vision and galvos.

- Removal of motion disturbances using ServoBoost™ software tool.

- Use of EtherCAT real time industry standard network.

- Motion simulator tool for application development.

- Modular approach, easy to expand.

- Centralised automation and synchronisation of 64 axes from one controller.

- High level programming, multi-tasking software for easy application development.

- UK based support and service.

Advanced Gantry Control Algorithms to:

- Simplify the process of timing multiple control loops

- Provide dynamic compensation of yaw

- Optimise the accuracy, velocity, stability and settling time

PING has revolutionised the golf equipment industry by utilizing modern computer and automation technology to achieve the highest levels of precision, performance, and quality in the design and manufacturing of their products. The latest generation club testing systems at PING were designed with ACS Motion Control solutions. The PING Man and PING Man Tee systems utilize the MC4U integrated control and drive solution, while the Shaft Fatigue test system uses SPiiPlusNTM motion and EtherCAT Controller and UDM drives.

”ACS Motion Control was an instrumental partner in our upgrade of the PING Man and PING Man Tee systems. The accuracy which we’re able to hold during testing has increased dramatically. The SPiiPlus MMI Application Studio is intuitive, logical, and was a snap to learn. The Scope and Watch tools, just to name a few, were vital during system installation. ACS’ highly knowledgeable and friendly Application Engineers helped us to quickly overcome issues during the development process. The modularity of the products has enabled us to consolidate dis-similar test systems (PING Man and Shaft Fatigue) under one motion control platform. Two entirely different applications, one development tool (SPiiPlus MMI Application Studio), one language (ACSPL+), one very happy engineering team.”

C.P. Test Engineer, PING

Ask a UK ACS Support Engineer

Contact us today!

If you are outside the UK and Ireland ACS support is available from sales@acsmotioncontrol.com

New from ACS

ECMsm

2 or 4 Axis Motion Controller with Integrated Servo Drives

- Controller and Drive Axes: 2 or 4

- Host PC/PLC/PAC Communication: TCP/IP, Ethernet/IP, Modbus, RS-232

- Controller Cycle Rate: 1kHz

- Drive Supply Input: 12-48Vdc

- Bus Voltage: Equal to drive supply input

- Max Current Output Per Axis: 5/10A

- Encoder Channels: 4 (AqB, Absolute, or SinCos)

- Mounting Type: Panel

- Functional Safety Options: STO & SS1

IDMma

2 or 4 Axis DS402 EtherCAT® Intelligent Drive Module up to 10/20A at 150VDC

- Communication Protocol: EtherCAT DS402 (CiA402) CoE

- Max EtherCAT Cycle Rate: 4kHz

- Real-Time ACSPL+ Program Threads: 4

- Drive Axes: 2 or 4

- Drive Supply Input: 24-150Vdc

- Bus Voltage: Equal to drive supply input

- Max Current Output Per Axis: 15/30A up to 100Vdc, 10/20A up to 150Vdc

- Mounting Type: Panel

- Functional Safety Options: STO & SS1

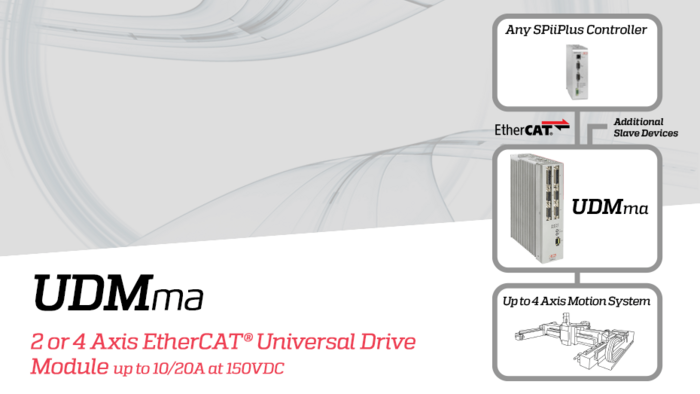

UDMma

2 or 4 Axis EtherCAT® Universal Drive Module up to 10/20A at 150VDC

- Drive Axes: 2, 4

- Drive Supply Input: 24-150 Vdc

- Bus Voltage: Equal to Vin

- Max Current Output Per Axis: 15/30A up to 100Vdc, 10/20A up to 150Vdc

- Encoder Channels: up to 4

- Mounting: Panel

- Functional Safety Options: STO, SS1

- Proprietary ACS Feature Options: ServoBoost, Non-Linear Control

LCM EtherCAT® Laser Control Module

Enables direct control of a laser source with full synchronization to motion

- The LCM is designed to meet the needs of laser processing system OEMs with demanding throughput and accuracy requirements.

- Working under any ACS SPiiPlus Platform EtherCAT master controller, the LCM tightly synchronizes control of a fixed beam laser with motion.

- Sub-microsecond latency enables high-accuracy laser micromachining, while high pulse frequencies enable high levels of throughput.

SPiiPlusSPC Smart Processing Commander

Machine Control Interface for High-Precision Laser Processing Applications

- Flexible CAD-to-motion import and design

- 2D and 3D processing modes

- Laser Control Module support for accurate fixed beam laser triggering, dynamic power control

- Dynamic Position Monitoring

- Flexible processing architectures

- Rich galvo scanner and vision system calibration features

- Pre-developed support for leading galvo, laser, and camera suppliers

- Customization Options via C# plugins

Laser Processing Control Solutions Brochure

Smarter Motion Control Solution for Faster Laser Processing Systems

ACS Promise

We are always ready to rise to the challenge to deliver smart, best-performing motion control solutions for the most demanding applications, developed and supported in partnership with you and in-line with your needs.

ACS Motion Control Brochure

High-Performance OEM Motion Control Solutions

ACS and its partners tailor motion control solutions with standard products to meet your unique requirements.

- Motion controllers

- Motion controllers with integrated drives

- Motor drives

- Drive interfaces

- Laser interfaces

- Auxiliary products

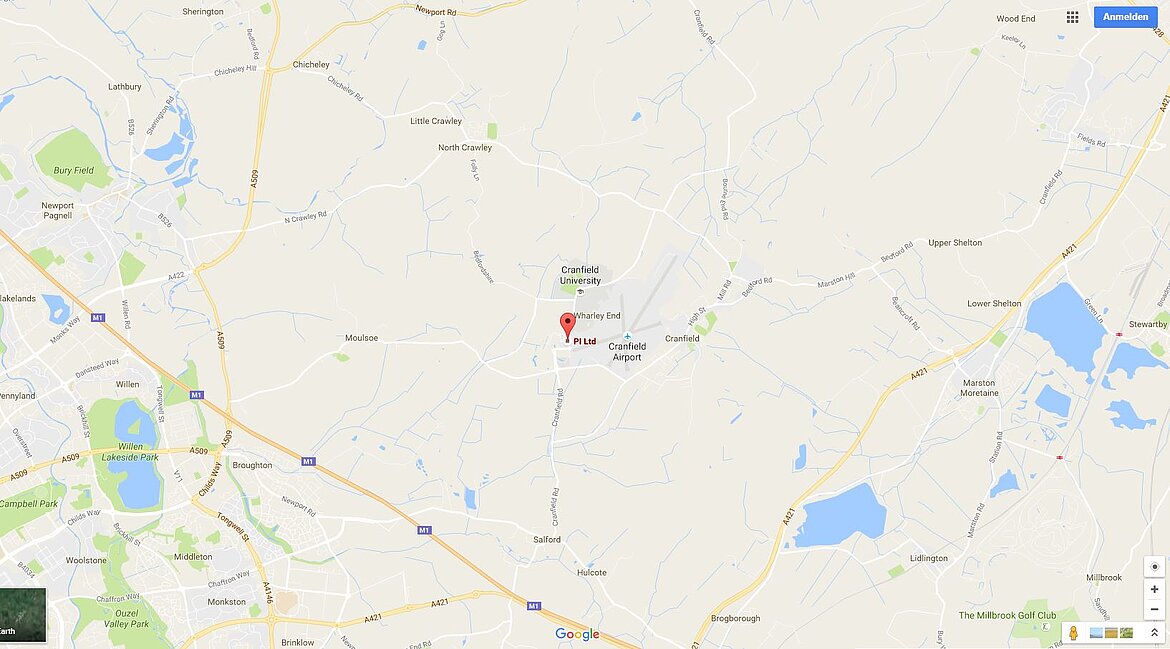

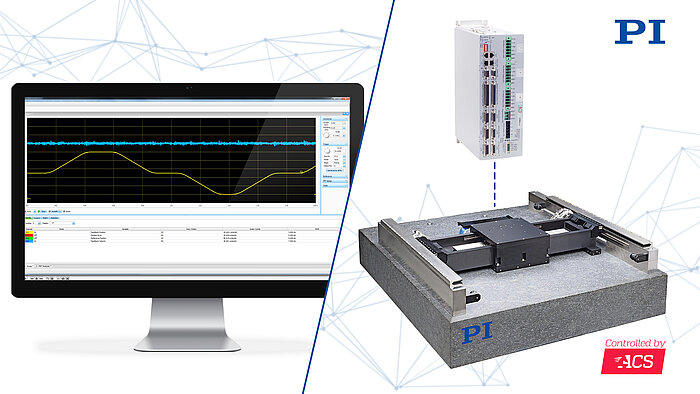

Smarter Gantry Control

Improve Throughput and Accuracy with Advanced MIMO Control Algorithm

- MIMO decoupled control of linear position and yaw displacement loops

- Independent tuning and optimization of linear and yaw control loops

- Dynamic cross-axis center of mass compensation

- Error mapping compensation (orthogonality, straightness...)

- Dual-loop gantry control

System Optimisation and Support

UK based support tailored to your needs

- System implementation, mechanics, controller and peripheral devices

- System optimisation including tuning

- Fault diagnosis including root cause analysis and corrective action

- Training

UK ACS Training Centre

Visit PI in Cranfield and learn about how ACS can help you improve the productivity, precision and quality of your process.

For more information about our PI Inspiration events click here.