PI Ceramic offers a wealth of experience and mature manufacturing processes in the complex development and production of piezoceramic components and actuators. From the composition and processing of the ceramic powder to metalization and polarization, the conditions of production are adapted individually to the ceramic material to achieve optimal material parameters in the finished piezo element.

Organization of Production Processes

All steps of the process, from the powder to the finished product, are certified and performed in-house, this assures the quality of the product at all times.

The entire production is controlled via ERP and Kanban systems and, by applying the Kaizen method, directed towards continuous improvement.

The quality of the PI Ceramic products and services is based on an effective >> Integrated Management System (IMS).

Precision Machining

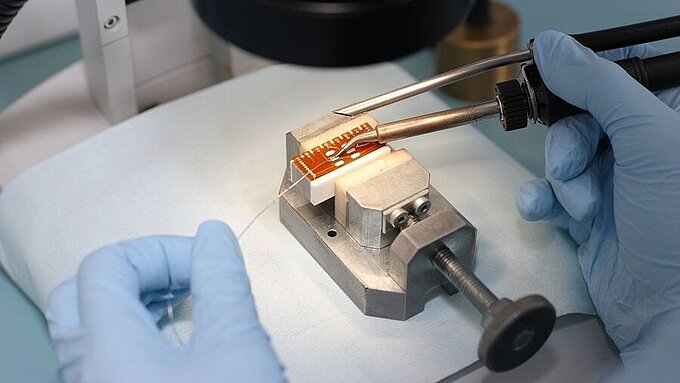

PI Ceramic employs processing techniques from the semiconductor industry in order to process the sensitive piezo ceramics with the highest precision. Special milling machines ensure exact shaping during the green state, in other words, prior to sintering.

Sintered ceramic blocks are processed with precision saws as used for the separation of individual wafers. Very fine holes, structured ceramic surfaces, and even complex, three-dimensional contours can be produced.

As all tools and machines are available in-house, PI Ceramic can offer convincing precision and flexibility for quantities ranging from 1 to 1,000,000.

Research Laboratories

In its in-house laboratories, PI Ceramic develops and optimizes piezo materials. This is where the quality of the materials used is monitored and where research into new materials is conducted. In particular the further development of lead-free piezo materials is an important challenge for laboratory research.

One of the core competencies of PI Ceramic is the improvement and specialization of piezo ceramics per se and of the production processes in terms of greater displacement with better characteristics.

Manufacturing and Onward Processing

Lead oxide, zirconium oxide and titanium oxide are the raw materials for the later lead zirconate titanate (PZT). These basic materials are used for producing the ceramic powders by mixing, milling, calcinating and presintering. Depending on the piezo material, the ceramic powders pass through various processing stages. This results in free-flowing, homogenous granulates, ideally prepared for further processing to piezoelectric components:

Special Manufacturing Processes

Special Manufacturing Processes

One of PI Ceramic's especially innovative manufacturing processes is the patented Multilayer Tape Technology PICMA®. These multilayer piezo actuators can be produced in virtually any shape.

Coating of Piezo Components

In addition to the development of an all-ceramic insulation for >> PICMA® actuators, PI Ceramic provides the option of coating >> piezo components. Parylene is a polymer with an excellent barrier effect against water vapor, moisture, organic and inorganic media, gases, acids, and alkalis. Due to special processing, the coating has important advantages over other polymers: no pore formation, consistent layer thickness, and polymerization on cold surfaces. The latter prevents a strain on the material caused by the increase in temperature during processing. As a thin, transparent coating, parylene protects piezoceramics of different shapes and sizes.