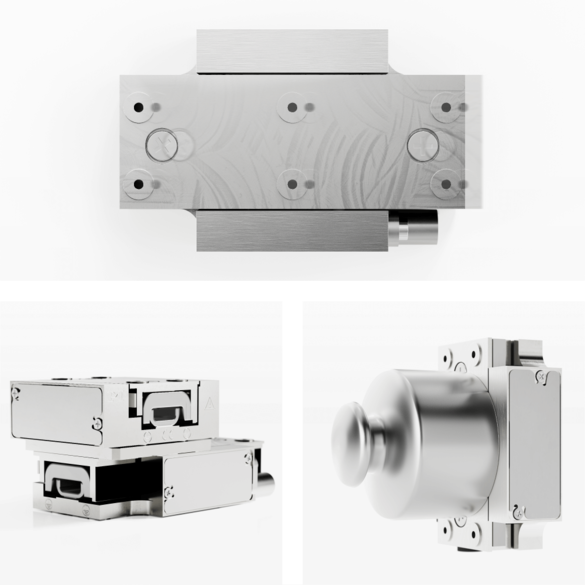

Maximum Precision in the Smallest Spaces

Miniature Linear Stage with Biphase Inertia Drive for Nanometer-Precise Positioning with High Long-Term Stability

Precise, Stable Positioning System for Demanding High-Tech Applications

Key challenges of modern high-tech positioning applications include long-term stable positioning, reproducible movements in the nanometer range, a compact design, and flexible configuration for use in small installation spaces. Even the slightest deviation can impair functionality. Therefore, the demands on resolution, stability, and integration capability are high. The B-421 BIX miniature linear stage has been developed to reliably meet these technical requirements.

Advantages at a Glance:

- Outstanding precision: Minimum incremental motion of 10 nm

- Stable: Self-locking mechanics for high position stability over long periods of time

- Resilient: High maximum payload and drive force

- Space-saving and flexible: Compact design and stackable for multi-axis combinations

- Precise positioning: High resolution and reproducibility

Talk to an expert

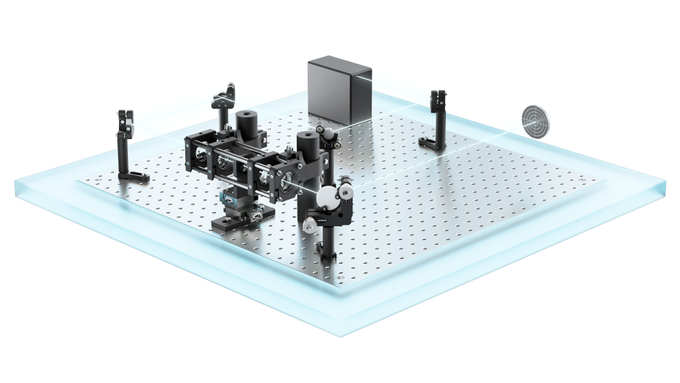

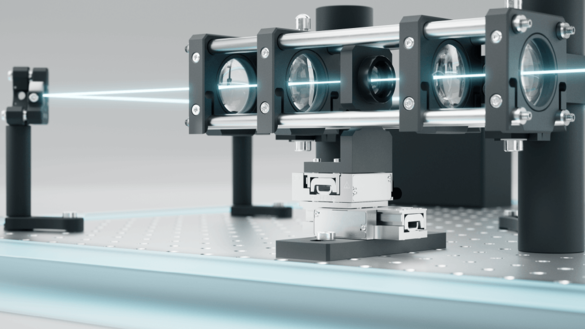

Exact Beam Shaping and Steering

The success of modern, high-precision systems depends particularly on the stable positioning of optical components with nanometer precision. In beam manipulation, typical requirements include long-term positioning of mirrors, diaphragms, and lenses, as well as the nanometer-precise alignment for reproducible beam steering. There is a demand for compact positioning systems that enable nanometer-precise motion and can be flexibly integrated into multi-axis setups. This is particularly important for beam quality in the semiconductor industry, such as in overlay metrology, and in microscopy for super-resolution microscopy methods like TIRF or STED.

With the B-421 BIX miniature linear stage, we take precision to the next level in quality assurance processes in the semiconductor industry—precisely where conventional systems reach their limits. Thanks to its compact design and precise motion in the nanometer range, we help our customers achieve reliable quality control and process optimization.

Dr. Cameron Hughes, Product Manager PI

Key Details in Brief

Key Details in Brief

Minimum incremental motion of 10 nm

Dimensions: 25 x 11 mm (width x height)

Travel ranges from 13 to 33 mm

Resolution: 6 nm

Maximum drive force of 2.5 N

Maximum payload of 0.5 kg (motion in X) and 0.15 kg (motion in Z)

User-friendly PIMikroMove software