- Unlimited Resolution

Piezo actuators convert electrical energy directly into mechanical energy and vice versa and allow for motions in the subnanometer range. There are no friction elements that limit resolution.

- Stiffness, Load Capacity, Force Generation

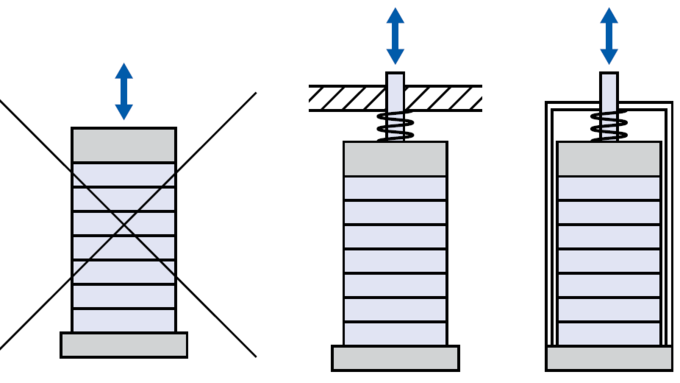

To a first approximation, a piezo actuator is a spring-and-mass system. The stiffness of the actuator depends on the elasticity module of the ceramic (approx. 25% of that of steel), the cross section and length of the active material, and other nonlinear parameters. Typical actuators have stiffnesses between 1 and 2,000 N/μm and compressive limits between 10 and 100,000 N. For tensile stresses, a casing with integrated preload or an external preload spring is required. Adequate measures must be taken to protect the piezo ceramic from shear and bending forces and from torque.

- Vacuum and Clean Room Compatible

Piezo actuators neither cause abrasion nor do they require lubrications. The all-ceramic insulated PICMA® actuators have no polymer coating and are thus ideal for ultrahigh vacuum applications.

- Operating Voltage

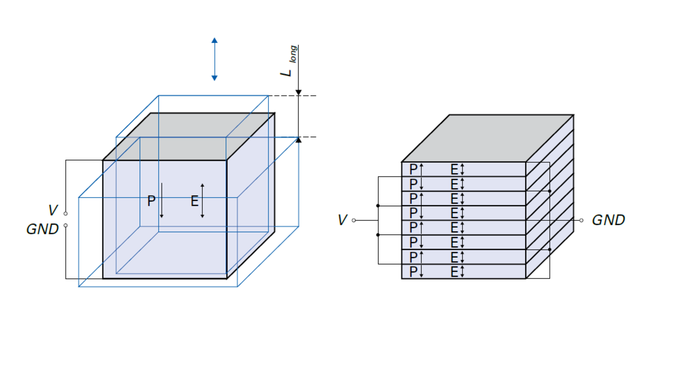

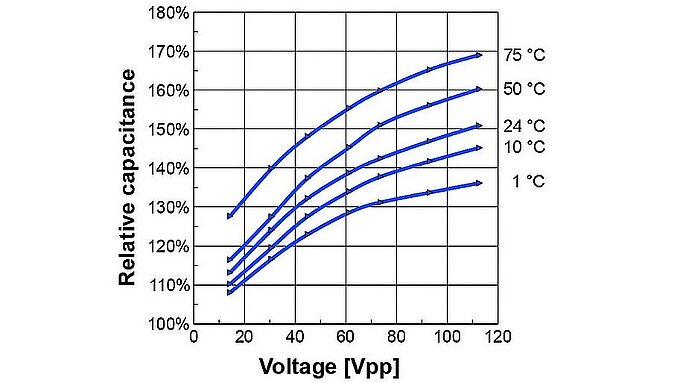

Two types of piezo actuators have become established:

Monolithic-sintered PICMA® multilayer actuators (low-voltage actuators) operate at voltages up to about 130 V and are made of ceramic layers from 20 to 100 μm in thickness.

Classical high-voltage actuators (PICA high-power actuators) are made from ceramic layers of 0.5 to 1 mm thickness and operate at voltages of up to 1000 V. PICA actuators can be manufactured with larger cross sections, making them suitable for larger loads than the more compact monolithic multilayer piezo actuators.

- High Force Generation

High-load piezo actuators capable of moving loads of several tons are available. They can cover travel ranges to 300 μm with resolutions in the subnanometer range.

- Position Resolution

The piezo ceramic itself works free of friction and theoretically has unlimited resolution. In practice, the resolution actually attainable is limited by electrical and mechanical factors:

a) Sensor and servo-control electronics, amplifiers: Amplifier noise and sensitivity to electromagnetic interferences (EMI) affect positional stability.

b) Mechanical parameters: Design and mounting precision issues concerning the actuator, preload and sensor can induce microscopic friction which limits resolution and accuracy. Piezo actuators reach subnanometer resolution and stability.