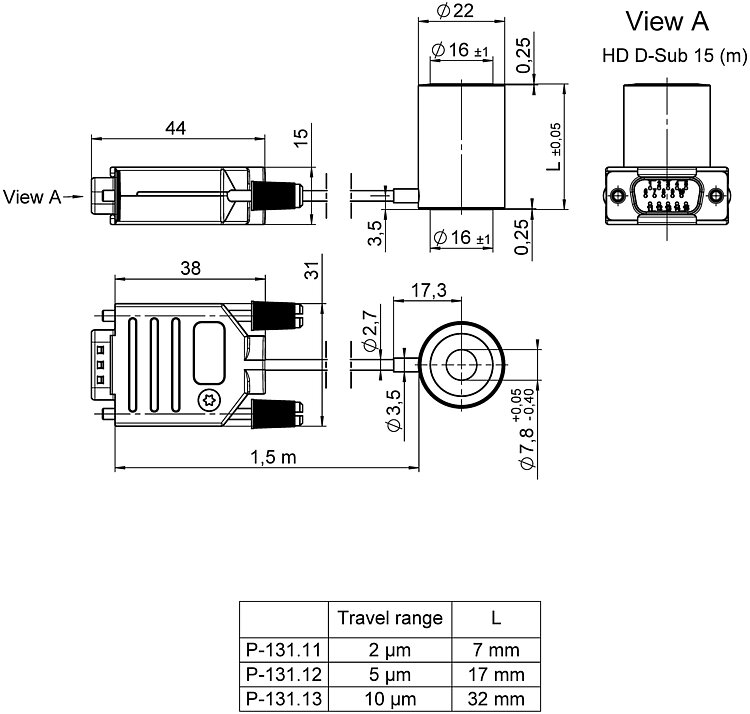

PIRest active shim; PIRest piezo actuator drive; 2 µm travel range (open loop); HD D-sub 15-pole (m); 1.5 m cable length

P-131 PIRest Actuators

Active Shims with Nanometer Resolution and Long-Term Stability

- Long-term stability without permanent power supply

- Easy readjustment of machines at inaccessible locations

- Avoids time-consuming manual adjusting processes

- Nanometer resolution and micrometer displacement

- Load capacity up to 4000 N per actuator

- Temperature sensor

Application fields

- Set-and-forget applications

- Adaptive mechanics

- Drift compensation

- Alignment of optical components

- Precision mechanics

- Static precision positioning

- Metrology / interferometry

Long-term stable positioning without permanent power supply

Once displaced, actuators with PIRest technology hold their position stable without permanent control voltage. Nanometer precision, maintenance-friendly and inexpensive adjustments are possible even at inaccessible locations.

High user-friendliness due to automatic configuration

Important operating parameters are stored on the mechanic's ID chip and are read out automatically when the electronics are switched on.

Specifications

Specifications

| Motion | P-131.11 | P-131.12 | P-131.13 | Tolerance |

|---|---|---|---|---|

| Active axes | Z | Z | Z | |

| Travel range in Z, open loop | 2 µm | 5 µm | 10 µm | ±20 % |

| Positioning | P-131.11 | P-131.12 | P-131.13 | Tolerance |

| Minimum incremental motion in Z | < 10 nm | < 10 nm | < 10 nm | |

| Drive Properties | P-131.11 | P-131.12 | P-131.13 | Tolerance |

| Drive type | PIRest | PIRest | PIRest | |

| Voltage for active adjustment | 120 V | 120 V | 120 V | max. |

| Voltage for for long-term stable position | 0 V | 0 V | 0 V | |

| Electrical capacitance | 3.4 µF | 10.2 µF | 20.4 µF | ±20 % |

| Mechanical Properties | P-131.11 | P-131.12 | P-131.13 | Tolerance |

| Stiffness | 1000 N/µm | 350 N/µm | 170 N/µm | typ. |

| Permissible push force in Z | 4000 N | 4000 N | 4000 N | max. |

| Miscellaneous | P-131.11 | P-131.12 | P-131.13 | Tolerance |

| ID chip | Yes | Yes | Yes | |

| Operating temperature range | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | |

| Connector | HD D-sub 15-pin (m) | HD D-sub 15-pin (m) | HD D-sub 15-pin (m) | |

| Cable length | 1.5 m | 1.5 m | 1.5 m | |

| Recommended controllers / drivers | E-135 | E-135 | E-135 | |

| Temperature sensor | Yes | Yes | Yes |

Travel range and minimum incremental motion: At room temperature.

Vacuum versions and customized versions available on request.

Downloads

Datasheet

Documentation

User Manual PZ291

P-131.11 PIRest Active Shim

User Manual PZ292

P-131.12 PIRest Active Shim

User Manual PZ293

P-131.13 PIRest Active Shim

Quote / Order

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

PIRest active shim; PIRest piezo actuator drive; 5 µm travel range (open loop); HD D-sub 15-pole (m); 1.5 m cable length

PIRest active shim; PIRest piezo actuator drive; 10 µm travel range (open loop); HD D-sub 15-pole (m); 1.5 m cable length