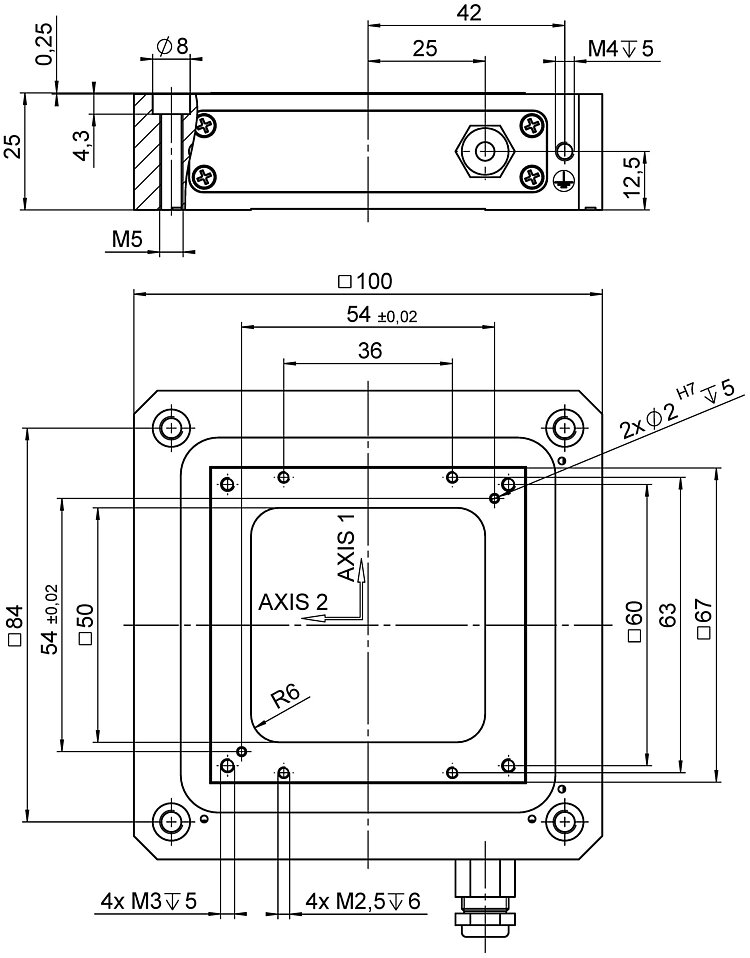

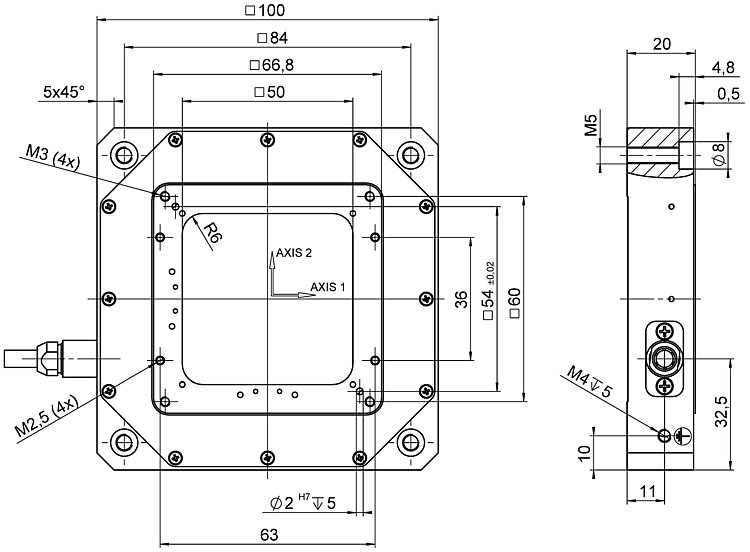

XY piezo nanopositioner; 100 µm × 100 µm travel range (X × Y); capacitive, indirect position measuring; D-sub 25W3 (m); 1.5 m cable length

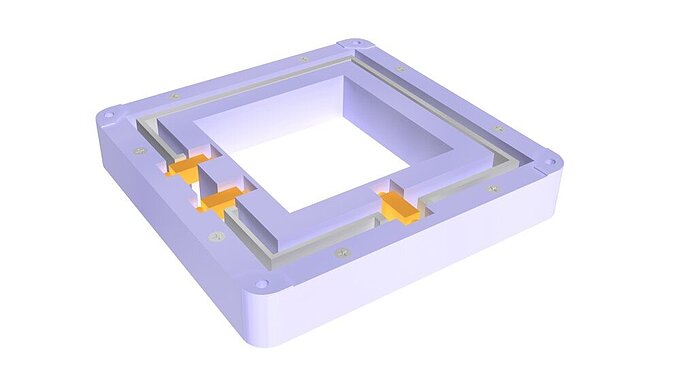

P-733.2 XY Piezo Nanopositioner

High-Precision XY Scanner with Aperture

- Travel ranges to 100 µm × 100 µm in X and Y

- Resolution to 0.1 nm due to capacitive sensors

- High velocity versions with direct drive

- Vacuum-compatible and nonmagnetic versions on request

- Parallel kinematics for higher accuracy and dynamics

- Parallel metrology for active compensation of guiding errors

- Zero-play, high-precision flexure guide system

- Clear aperture 50 mm × 50 mm for transmitted-light applications

Application fields

- Scanning microscopy

- Confocal microscopy

- Mask/wafer positioning

- Surface measuring technology

- Nanoimprinting

- Micromanipulation

- Image processing / stabilization

- Nanopositioning with high flatness and straightness of motion

Outstanding lifetime thanks to PICMA® piezo actuators

The PICMA® piezo actuators are all-ceramic insulated. This protects them against humidity and failure resulting from an increase in leakage current. PICMA® actuators offer an up to ten times longer lifetime than conventional polymer-insulated actuators. 100 billion cycles without a single failure are proven.

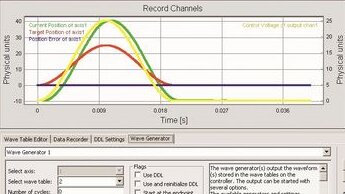

Subnanometer resolution with capacitive sensors

Capacitive sensors measure with subnanometer resolution without contacting. They guarantee excellent linearity of motion, long-term stability, and a bandwidth in the kHz range.

High guiding accuracy due to zero-play flexure guides

Flexure guides are free of maintenance, friction, and wear, and do not require lubrication. Their stiffness allows high load capacity and they are insensitive to shock and vibration. They work in a wide temperature range.

Automatic configuration and fast component exchange

Mechanics and controllers can be combined as required and exchanged quickly. All servo and linearization parameters are stored in the ID chip of the D-sub connector of the mechanics. The autocalibration function of the digital controllers uses this data each time the controller is switched on.

Maximum accuracy due to direct position measuring

Motion is measured directly at the motion platform without any influence from the drive or guide elements. This allows optimum repeatability, outstanding stability, and stiff, fast-responding control.

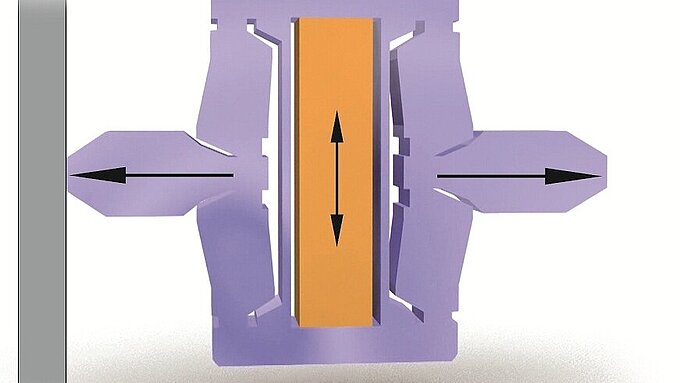

High dynamics multi-axis operation due to parallel kinematics

In a parallel-kinematic multi-axis system, all actuators act on a common platform. The minimum mass inertia and the identical design of all axes allow fast, dynamic, and nevertheless precision motion.

Specifications

Specifications

| Motion | P-733.2CD | P-733.2CL | P-733.2DD | Tolerance |

|---|---|---|---|---|

| Active axes | X ǀ Y | X ǀ Y | X ǀ Y | |

| Travel range in X | 100 µm | 100 µm | 30 µm | |

| Travel range in Y | 100 µm | 100 µm | 30 µm | |

| Travel range in X, open loop, at -20 to 120 V | 115 µm | 115 µm | 33 µm | +20 / -0 % |

| Travel range in Y, open loop, at -20 to +120 V | 115 µm | 115 µm | 33 µm | +20 / -0 % |

| Linearity error in X | 0.03 % | 0.03 % | 0.03 % | typ. |

| Linearity error in Y | 0.03 % | 0.03 % | 0.03 % | typ. |

| Pitch (Rotational crosstalk in θX with motion in Y) | ± 3 µrad | ± 3 µrad | ± 5 µrad | typ. |

| Pitch (Rotational crosstalk in θY with motion in X) | ± 3 µrad | ± 3 µrad | ± 5 µrad | typ. |

| Yaw (Rotational crosstalk in θZ with motion in X) | ± 10 µrad | ± 10 µrad | ± 10 µrad | typ. |

| Yaw (Rotational crosstalk in θZ with motion in Y) | ± 10 µrad | ± 10 µrad | ± 10 µrad | typ. |

| Positioning | P-733.2CD | P-733.2CL | P-733.2DD | Tolerance |

| Unidirectional repeatability in X | ± 2 nm | ± 2 nm | ± 2 nm | typ. |

| Unidirectional repeatability in Y | ± 2 nm | ± 2 nm | ± 2 nm | typ. |

| Resolution in X, open loop | 0.2 nm | 0.2 nm | 0.1 nm | typ. |

| Resolution in Y, open loop | 0.2 nm | 0.2 nm | 0.1 nm | typ. |

| Integrated sensor | Capacitive, indirect position measuring | Capacitive, indirect position measuring | Capacitive, indirect position measuring | |

| System resolution in X | 0.3 nm | 0.3 nm | 0.1 nm | typ. |

| System resolution in Y | 0.3 nm | 0.3 nm | 0.1 nm | typ. |

| Drive Properties | P-733.2CD | P-733.2CL | P-733.2DD | Tolerance |

| Drive type | PICMA® | PICMA® | PICMA® | |

| Electrical capacitance in X | 6 µF | 6 µF | 6.2 µF | ±20 % |

| Electrical capacitance in Y | 6 µF | 6 µF | 6.2 µF | ±20 % |

| Mechanical Properties | P-733.2CD | P-733.2CL | P-733.2DD | Tolerance |

| Stiffness in X | 1.5 N/µm | 1.5 N/µm | 20 N/µm | ±20 % |

| Stiffness in Y | 1.5 N/µm | 1.5 N/µm | 20 N/µm | ±20 % |

| Resonant frequency in X, unloaded | 500 Hz | 500 Hz | 2230 Hz | ±20 % |

| Resonant frequency in X, under load with 120 g | 370 Hz | 370 Hz | — | ±20 % |

| Resonant frequency in X, under load with 200 g | 340 Hz | 340 Hz | 1550 Hz | ±20 % |

| Resonant frequency in Y, unloaded | 500 Hz | 500 Hz | 2230 Hz | ±20 % |

| Resonant frequency in Y, under load with 120 g | 370 Hz | 370 Hz | — | ±20 % |

| Resonant frequency in Y, under load with 200 g | 340 Hz | 340 Hz | 1550 Hz | ±20 % |

| Permissible push force in X | 50 N | 50 N | 50 N | max. |

| Permissible push force in Y | 50 N | 50 N | 50 N | max. |

| Permissible push force in Z | 50 N | 50 N | 50 N | max. |

| Permissible pull force in X | 20 N | 20 N | 20 N | max. |

| Permissible pull force in Y | 20 N | 20 N | 20 N | max. |

| Permissible pull force in Z | 20 N | 20 N | 20 N | max. |

| Overall mass | 580 g | 580 g | 580 g | ±5 % |

| Material | Aluminum | Aluminum | Aluminum | |

| Miscellaneous | P-733.2CD | P-733.2CL | P-733.2DD | Tolerance |

| Operating temperature range | -20 to 80 °C | -20 to 80 °C | -20 to 80 °C | |

| Connector | D-sub 25W3 (m) | LEMO FFS.00.250.CTCE24 | D-sub 25W3 (m) | |

| Cable length | 1.5 m | 1.5 m | 1.5 m | ±10 mm |

| Recommended controllers / drivers | E-503, E-505, E-610, E-621, E-625, E-712, E-727 | E-503, E-505, E-610, E-621, E-625, E-712, E-727 | E-503, E-505, E-610, E-621, E-625, E-712, E-727 | |

| Sensor connector | — | LEMO FFA.00.250.CTLC31 | — |

P-733.2DD: Linearity error with digital controller. With analog controllers, the typical linearity error for direct drive positioners can be up to 0.1 %.

The resolution of the system is limited only by the noise of the amplifier and the measuring technology because PI piezo nanopositioning systems are free of friction.

Downloads

Product Note

Product Change Notification Piezo Actuator Driven Products

Datasheet

Documentation

User Manual PZ103

P-733, P-734 Piezo Nanopositioning Systems with Capacitive Sensors

3D Models

P-733 3-D model

Brochure

Microscope Stage Configurator

Sample Stages and Holders for Inverted Microscopes

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

XY piezo nanopositioner; 100 µm × 100 µm travel range (X × Y); capacitive, indirect position measuring; LEMO connectors; 1.5 m cable length

XY piezo nanopositioner; 30 µm × 30 µm travel range (X × Y); capacitive, indirect position measuring; D-sub 25W3 (m); 1.5 m cable length

How to Get a Quote

Ask an engineer!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.

Technology

PICMA® Technology

Highly reliable and extended lifetime through the patented manufacturing process for multilayer actuators.

Vacuum

Careful handling, adequate premises: PI does not only have the necessary equipment for the qualification of materials, components and final products, but also has many years of experience with regard to HV und UHV positioning systems.

Flexure Guiding Systems

Flexure guides from PI have proven their worth in nanopositioning. They guide the piezo actuator and ensure a straight motion without tilting or lateral offset.

Digital Motion Controllers

Digital technology opens up possibilities for improving performance in control engineering which do not exist with conventional analog technology.

Capacitive Sensors

Capacitive sensors are the metrology system of choice for the most demanding nanopositioning applications.

Piezo Positioning Systems with Parallel Kinematics

In a parallel-kinematic, multi-axis system, all actuators act directly on a single moving platform.