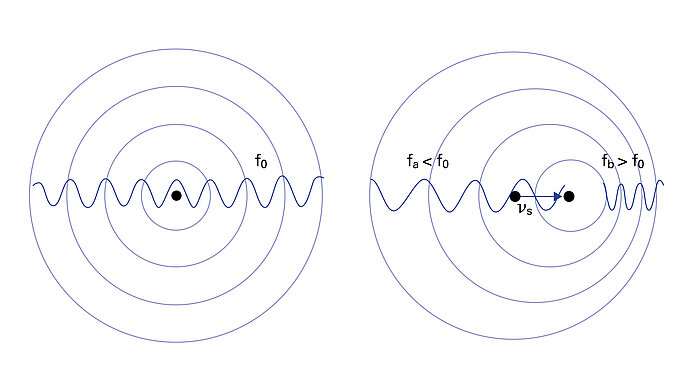

In addition to piezo components, PI Ceramic also supplies complete transducers, which are developed together with you according to your application specifications. PI Ceramic offers you options for different quantities up to large series with project-related effort. The ultrasonic transducers can be operated in a wide range of applications with frequencies up to several megahertz. These include OEM assemblies for ultrasonic flow or level measurement.

However, special applications have special requirements – PI Ceramic develops transducer together with you exactly according to your application!

All Process Steps under One Roof

PI Ceramic has many years of experience and sophisticated manufacturing technologies, not only in the complex development and manufacture of piezoceramic components and actuators, but also in assembly and connection technology.

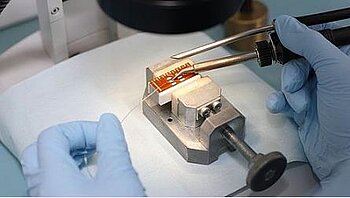

The processes range from gluing and joining ceramic disks to mechanical post-processing such as lapping and grinding for minimum geometric tolerances to soldering the contacts or assembling under the microscope.

PI Ceramic's production facilities are equipped with cleanrooms that are used both for manufacturing and for the subsequent qualification of the products. PI Ceramic unites all process steps under one roof and has the necessary know-how to implement customer-specific adaptations in the shortest possible time and to the highest quality.

From Single Unit to Large Series Production

At PI Ceramic, qualified employees manufacture individual pieces by hand. This manual production offers a high degree of flexibility: Individual functional samples can be realized quickly. Preassembled stranded wires, and printed circuit boards are soldered by hand even for small quantities.

If small or large series are required, production is semi and fully automated. Automated production steps can be for example, the application of adhesive dots or screen printing. To ensure constant process parameters, PI Ceramic uses semi-automated soldering processes such as light soldering.

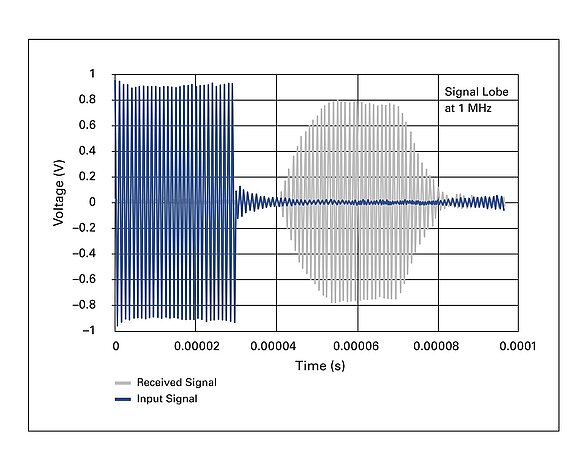

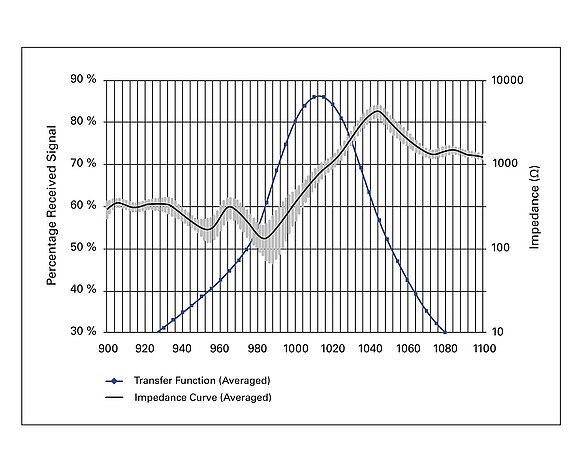

Finally, it is possible to evaluate the transducer and tailor it to the application, e.g., >> Measuring Impedance for Determining the Ultrasonic Power as well as other sound characteristics or the characterization of the developed transducers with a high-precision laser scanning vibrometer.