High-Precision Laser Processing for Wafer Dicing

High Guiding Accuracy – Exceptional Velocity Control – High Repeatability

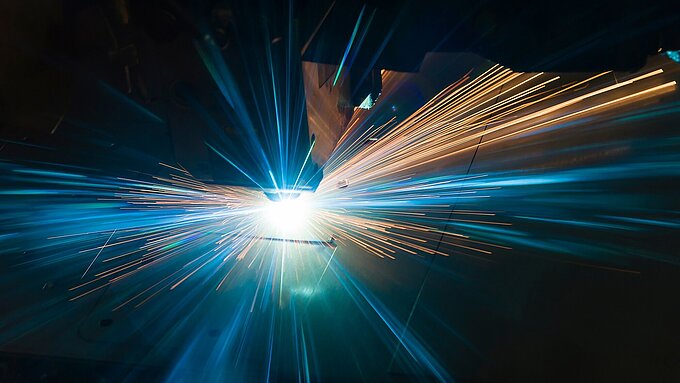

Manufacturing chips and microchips involves cutting the wafers, using a process known as wafer dicing, into small square or rectangular “chips” or “die”. Typical challenges to consider in wafer dicing applications are: To position the cut accurately, to minimize the losses of material, and to minimize distortions of the components. While at the same time, the maximum possible machining speed must be achieved. As the requirements are constantly increasing, laser dicing has become the preferred dicing technology. This noncontact laser process is flexible and avoids flaking at the cutting edges. The good quality of the edges, which is one of the decisive factors for fracture resistance, can be further improved with various automated postprocessing processes. This significantly reduces production waste and, therefore, saves production costs. Accordingly, laser-dicing processes also demand motion systems that offer high accuracy and high straightness at high velocities.

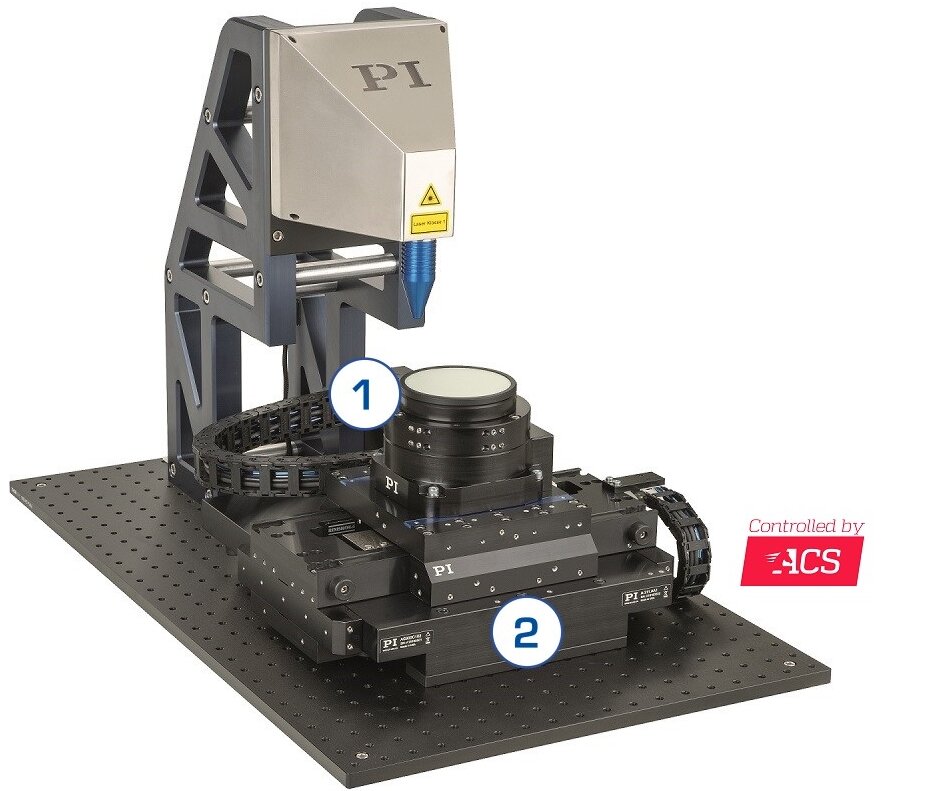

Rotation Axis - Wafer Orientation and Correction

- Air bearing rotation stage

- Direct-drive cogless motion

- Superior travel accuracy, flatness, and wobble performance

- High stiffness and load capacity

- Cleanroom compatible

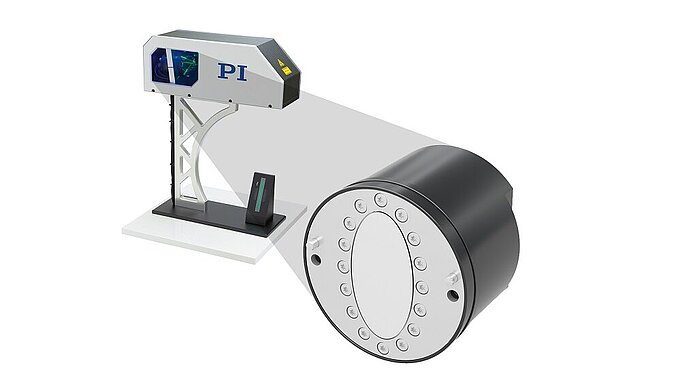

>> A-623 PIglide Rotation Stage with Air Bearings

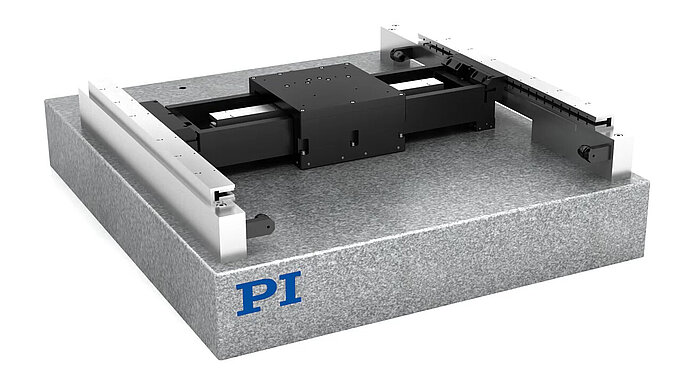

Scan Axis

- XY planar air bearing stage

- High velocities and accelerations

- Excellent geometric performance

- Resolution to 1 nm

- Low profile for limited installation space

- Cleanroom compatible

>> A-311 PIglide Planar Scanner with Air Bearing

Motion Control

- High performance EtherCAT® motion controller presented in a 19”-rack with integrated drives, power supplies, and functional safety.

>> A-814 PIglide Motion Controller - NanoPWM™ drive technology enables nanometer tracking error and optimal velocity. >> NanoPWM™ Drives

- Advanced servo control algorithms such as >> ServoBoost™

Downloads

Motion Systems for Electronics Manufacturing

PLACE -> ALIGN -> PROCESS -> INSPECT -> TEST

Automation Platforms for Laser Material Processing

Precision – Throughput – Synchronized Motion